|

Introduction

I have written these notes about a cellar that I built in the Mid North of South Australia in the hope that they might be of some use to others who are contemplating building a cellar. I would like to have been able to read about other people's experiences before building my cellar, it might have made my job easier. The notes also provide a record for me, and I enjoy writing.Where I live maximum daily temperatures in the high 30s Celsius are not unusual in summer and frosts are common in the winter. All year around the temperature a couple of metres or more underground are a comfortable 18 degrees. (In a hotter climate a similar cellar to the one I built could also be cooled passively by nocturnal radiation.)

We heat our houses in winter and cool them in summer and most of us give very little thought to the millions of tonnes of soil and rock beneath our feet that is at a very pleasant temperature. In a world where reducing energy consumption is desperately important because of climate change and ocean acidification why don't we make more use of in-ground building?

Underground living has been very effectively adopted in the northern South Australian town of Coober Pedy.

I've written and provided photos of some Coober Pedy examples of underground architecture on

another page on this site.

Refuge from bushfire I am not an expert in bushfires. Before building a cellar as a refuge you might be wise to discuss the matter with someone who has had experience in the field.

Following the Victorian bushfires of February 2009, in which more than a hundred people were killed, it's worth stressing that a cellar is not just a refuge from summer heat, it is also available as an excellent refuge from bushfires. Both heat and bushfires are going to be more common with climate change; perhaps even more importantly, days of fire danger levels greater than what has been known as 'extreme' will be more frequent.

It would be important to seriously consider whether your house or other structures or trees might block your escape from your cellar following a bushfire. You would also need to consider the possibility of a wooden cellar door catching fire and the consequences of that.

The cellar would have to be the last resort. Obviously you wouldn't be able to protect your house while you were taking refuge in a cellar.

Small, simple, fire refuge?

It would not be necessary to build a big cellar like the one discussed on this page, something much smaller and simpler could be used. It would be sufficient to dig a hole about 2m diameter, line it with bricks or stone and put a reinforced concrete slab on top with a steel hatch in it. Cover most of the slab with a little soil. You'd need a ladder beneath the hatch, and before you had to use it take down as many folding chairs as you needed.The soil would protect the cellar and its occupants from the radiant heat of the fire. There would be radiant heat from the steel hatch, but I suspect that would not be dangerous in the short time involved.

If there was any possibility of having trees or limbs fall on top of the cellar then it would be as well to put a steel tripod-frame over the top to ensure that they could not block the hatch and stop you from being able to get out.

Such a simple cellar will probably fill up with water in a wet period,

but the water would almost certainly be long gone before any bad fire.

An option, if the land was sloping, would be to put in a drain from the

bottom of the cellar to a lower point on the hillside.

Methods of building cellars

In Australia it is possible to buy ready-made concrete cellars that need only be placed into a hole in the ground and then have earth replaced around them. These are quite expensive and are very heavy and therefore expensive to transport from the point of manufacture to the point of installation. They do not seem generally to be designed for covering with a significant depth of earth (needed for good insulation). Access is by steps via a hole in the roof of the cellar, so some structure to protect the top of the stairway from the weather must be built over the cellar. It seems to me that these cellars would be best when placed beneath a new house before construction of the house itself.It is also possible to build a very simple cellar by burying a shipping container. It is questionable how long the walls and roof of the container would withstand the pressure from the soil, and the steel would probably rust very quickly, especially in areas with relatively high rainfalls and acid soils (such as in my case). I seriously considered using a shipping container and various methods to control rusting and protect the container from soil pressure, but finally gave up the idea as impractical.

Some cellars are based on a concrete tank built on site

in an excavation and then covered with soil, as is mine.

These notes

deal primarily with a 90 cubic metre cellar set into an excavation and

covered with mulch and soil.

Notes on digging the hole

The big excavator (shown digging the drain in one of the photos on the right) dug the pit in two and a half hours. I could not have dug it by hand if I had devoted two and a half months to the work! Some of the sixty tonnes of earth and rock removed was rock that was so hard that I could make little impression on it with a heavy crowbar.The cost of earthmoving was only about 5% of the total cost of constructing the cellar.

|

|

Contractors

All contractors, other than the one who did the concreting work, were based in the Clare Valley. (The concreting was specialised.)The main hole and most of the drain was dug by S.C. Heinrich using the big excavator shown digging the drain in the photo at the right. The tidying-up of the hole and the spreading of the base gravel was done by Mark Harrold's mini-excavator also shown in a photo on the right.

The concrete part of this cellar was built by Adelaide Hills Concrete Tanks, PO Box 902 Strathalbyn 5255, South Australia. Phone 08 8391 2013, mobile 0408 365 551. It is covered by a twenty year written guarantee.

Electrical wiring was done by David Bond.

The doors were built and installed by Craige Lloyd (Vision Builders), Blyth. 08 8844 5180, mobile 0419 188 089.

The contractors had no input into this Internet page and I have no financial arrangements with any of the contractors apart from the building of this cellar.

Another South Australian specialist in building concrete cellars is

Hyteck Concrete Products,

Paringa, phone 08 8595 5266, mobile 0414 812 220.

Why build a cellar?

In Clare (Mid-North South Australia) the winters are cold enough for some form of heating to be needed and the summers are hot enough for cooling to be necessary for comfort. Just a metre below the houses that are consuming energy for heating and cooling the temperature of the subsoil or rock is a constant and comfortable temperature all year around. I measured the temperature in two wells on my place and found it to be 18 degrees Celsius in both. Conservation of energy is becoming more and more important because of greenhouse and ocean acidification.In South Australia electricity for running air conditioning (home cooling) is at its least reliable when needed most: in periods of exceptional heat, simply because the supply system is then under its greatest load.

The greatest fire hazard occurs on exceptionally hot and windy days. On such days power lines expand both from the heat due to the weather and due to the high current in the wires. This causes the lines to sag more and combined with the winds they are more likely to clash together and cause sparks and fires. Also heat and wind makes branches and trees more likely to fall over power lines and cause fires. For these reasons the electricity supply is sometimes switched off as a precaution on hot windy days.

Using a cellar as a means of staying cool not only avoids the problem of unreliable electrical supply for the user, but also helps to reduce one of the causes of the problem: peak demand. So from the point of view both of the user of the cellar and those running the electrical grid, cellars are a good way of staying cool on exceptionally hot days.

Any increase in one's level of self-sufficiency, and independence from the electricity grid, must be a good thing.

A cellar, such as this one, is a safe refuge from

bushfires.

Engineering and water matters

While the principle of the cellar is simple, there are many practical complications in cellar construction.This cellar is about 7.4m diameter and 2.1m high inside, with an internal volume of 90 cubic metres. The concrete roof weighs about 15 tonnes and a layer of soil 20cm thick over this would weigh an additional 15 tonnes. The whole cellar must be made to safely handle these weights.

As the cellar is mostly below ground level it must be able to keep out the water that will saturate the surrounding soil in a wet winter, and any storm water run-off. This particular cellar, being basically a water tank, keeps water out quite well; as of 2009/06/26 I have had it almost three years, and have not seen any indication of leakage through the concrete.

However, the join between the walls and the roof do weep when the soil adjacent becomes saturated – which in my area is uncommon. The floor and walls were poured first and in one piece; the roof was added later so there is a 'crack' beneath the roof.

The round shape resists pressure from the surrounding earth, which is considerable when it becomes very wet. Gravel beds and perforated pipes were laid for three metres beneath each abutment to stop the earth near the abutments from becoming waterlogged and slumping (see photos). A 100mm drain pipe takes water from the excavation near the cellar door down a trench to a lower point on the hill slope (see photos).

|

|

Purpose of this cellar

It is used for a constant temperature store for garden produce, wine and olive oil, as a computer room, a bedroom, and a living room. It is a place to escape the heat of summer. It may be used for wine making at some time in the future.Pros and cons of a cellar

Advantages |

Disadvantages

|

|---|---|

|

|

|

|

Sustainability

In the late twentieth century Western world, keeping a building at the desired temperature has generally been done by energy consuming active methods. A cellar (at least in South Australia) stays at a very useful and comfortable temperature passively, without any energy requirement.Any intelligent and open-minded person knows that our society must reduce its production of greenhouse gasses. While making the cement that is used for building a cellar does result in a substantial amount of carbon dioxide being released into the atmosphere, once constructed the energy saving over the life of the cellar will result in a much greater saving of emissions.

One of the disadvantages of cellars is that they are not well suited to

the use of natural daylight. It is difficult to use natural lighting while

keeping heat from entering or exiting.

However, 20 Watts of LED lighting, so long as it is well placed, is quite enough for reading (3 Watts of LED lighting is quite enough for a reading light above a bed), using a computer, and many other activities; 30 Watts goes nowhere for heating or cooling.

The great advantage of cellars is in their ability to maintain temperatures

within fairly narrow limits, this is the key point.

Carbon dioxide calculations

About 0.9 tonnes of the greenhouse gas carbon dioxide is released into the atmosphere for each tonne of cement manufactured. The 90 cubic metre cellar described on this page contains about 50 tonnes of concrete and about 5 tonnes of cement, therefore the resultant amount of carbon dioxide released was about 4.5 tonnes. This is a substantial amount by any measure.

|

The steel reinforcing used in the cellar would probably be responsible for another tonne or so of carbon dioxide.

A concrete cellar should last at least twenty, and quite probably fifty or a hundred years (in April 2016 it was nearly ten years old and, so far as I could see, as good as new). Of course a cellar is also capable of keeping many cubic metres of stores at a fairly constant temperature all year around, something that would otherwise require a large refrigerated cool-room.

I have calculated the greenhouse CO2 that my wife and I are responsible for releasing in 2006 (including the building of this cellar) at my CO2 balance.

|

|

Other features of this cellar

Notes on the method of construction and the size and shape of my cellar are given in the section on Engineering and water matters. Several other features are significant.Site

The cellar is built into a gently sloping hillside. The floor of the cellar is about 1.5m below natural ground level on the upper side and about 1m below ground level on the lower part of the slope, near the door of the cellar. The slope of the hill allowed the cellar pit to be drained by natural flow through a 20m buried drain running down the hill.Doors

There is only one doorway with two doors. An inner wooden door (which includes a small hatch for flow-through ventilation) opening inward, and an outer screen door opening outward. The doorway has a clear metre's width to allow moving large items in and out. The door is accessed by a ramp that has a fall of around a metre.Flow through ventilation

Opposite the door, in the roof, is a 14cm diameter hole which is capped with a spinning ventilator. This, together with the small hatch in the door, provides sufficient ventilation to keep the air fresh inside. Leaving the wooden door open, but the screen door closed, provides fairly free ventilation (also see my notes on temperature control). Closing the wooden door but leaving its little hatch open provides limited ventilation. Closing the hatch minimises ventilation.How to do it better

If I was to start again from the beginning I might add some form of skylight. A necessary feature of such a skylight would be the ability to close it to minimise undesired heating from the sun. Obviously possible entry of rain water and storm water runoff would also need to be guarded against. A skylight would have to add significant complexity and cost, and with modern LED lights and green electricity, electric lighting is very cheap and has low environmental impact.I would also consider ways of increasing ventilation as a way of temperature control. The ideal might be a large skylight that can be in any one of four states:

- open to allow light and ventilation (but screened to keep out vermin);

- open only to light;

- open to ventilation, but closed to light;

- entirely closed.

An extractor fan could be used to maximise air flow, but has the disadvantage of being noisy and consuming electricity. Perhaps it is possible to buy quiet extractor fans; if so they could be useful to force ventilation when one might want to replace excessively cold air in the cellar in winter with the warmer air of a pleasant winter's day.

Another aproach would be to build your cellar first, then your house on top of your cellar; the roof of the cellar could be integrated into the floor slab of your house. The cellar could project beyond the house on one (or more) sides and ventilation and a sky-light could be placed in the roof of the cellar at that point.

|

|

|

Passive cooling by

nocturnal radiation

Radiative cooling

Temperatures fall at night, but in the height of summer in my location

even minimum overnight air temperatures can be too warm to be comfortable.

| ||||

|

|

How did this happen? At night, especially when there is a clear sky (as there usually is in the summer where I live) heat is radiated away into space. A slab of rock is quite a good radiator, and can lose heat by radiation faster than the surrounding air can warm it. (The bottom of the slab, which received radiation from the soil below, was at 16°.)

How can this be used to advantage?

A cellar, or for that matter a room, could be built with a concrete (or stone) slab roof. During the day the roof could be covered with insulation to stop it being warmed by sun light or the warm air; at night the insulation could be moved away so that the slab could radiate heat away into space.The experiment with the stone slab suggests to me that it would be possible to cool the roofing slab to around seven degrees below the minimum air temperature on a cloudless night. (The roof slab of my cellar is 150mm thick, so would be slower to cool than the 100mm stone slab of the experiment; on the other hand, the air beneath the roof slab would probably be cooler than the air beneath the stone slab.)

How would you make the insulated covering easily moved? Perhaps it could be made into a rigid 'slab' which could be rolled on or off the cellar on rails? Alternatively the cover could be folded up in the manner of the covers of a ship's hold.

|

|

The passive cooling by nocturnal radiation could be augmented using

evaporation.

I've written a bit on this on

another page on

this site.

False skylight

A cheap, environmentally friendly and effective way of lighting a cellar during daylight hours would be by using a False Skylight such as that described in the ReNew magazine issue 108. The article describes a system that uses a solar panel on the roof powering several bright light emitting diodes (LEDs) inside. The writer had built a system with a 10 Watt solar panel and five 3 Watt LEDs with switching so that all five or only four LEDs would be powered at any particular time. No components other than the panel, some simple wiring, a single switch, and the LEDs was required; the total cost was less than $300.Temperature control

I have found that my cellar can be cooled by maximising air circulation when the outside temperature is low and minimising circulation when the outside temperature is high. I have also found that having the screen door open provides much more air circulation than having the screen door closed. Of course entry of moths, mosquitos, flies and rodents must be considered if the screen door is to be left open. (Also see my notes on flow-through-ventilation in the section on other features of this cellar.)Leaving the solid door open, and the screen door closed, all of one cool night might only lower the temperature by a degree, but this is useful as once cool it does not quickly heat up again.

In winter, when and if the sun shines in the afternoon (not common in Clare winters), the wooden door can be left open in the afternoon to allow the sun to shine in and slightly warm the cellar (see photo).

I found that about 25 or 30cm of soil and mulch on the roof, with a cover of plants, or at least mulch, is sufficient to keep the cellar from getting above 24 degrees through summer in all but exceptional heat-waves (it has got to 25.5 degrees). The aim of the plant cover is to shade the soil. In the first summer I planted pumpkins, for a quick result; then Australian native groundcover plants, which have a modest need for water.

I believe that a Vaulted entrance would greatly

improve the long-term temperature stability of the cellar, as it is around

the entrance where the cellar is most exposed to sun and air.

| Cellar entrance 2014/01/12 |

|---|

|

|

The roof, of second hand galvanised iron, was erected in

September 2010.

It keeps most of the direct sunlight off the exposed concrete and door, and

keeps most of the rain off the woodwork of the door frame and inner door.

Heart-leafed ice plant, Aptenia cordifolia, and creeping Boobiala, Myoporum Insulare are the plants hanging down the wall and covering the stone abutments. Both are drought resistant. |

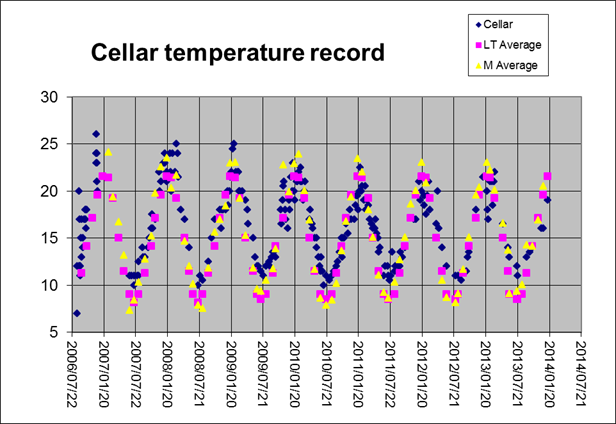

Temperature record

|

The maximum temperature I recorded in the cellar in the first summer was 25° C, while the outside temperatures got into the low forties on a number of days. This was before I had as much soil and vegetation cover on the roof as I wanted. With a thicker cover of soil and more fully developed vegetative cover it became unusual for summer temperatures in the cellar to go above 23° (the readings of around 25° in 2009 occurred during a record heatwave).

As mentioned elsewhere, the temperature deep in the ground in my area is 18° C.

The temperature in the cellar in winter gets down to was 10 or 11°; outside the cellar, frosts are common. I have made no attempt to heat the cellar, apart from letting the afternoon sun shine in through the door, and leaving the wooden door open, on some of the warmer days. Typically, the temperature does not vary by more than a half a degree in a day.

It is interesting to note that the more recent summer temperatures in the cellar have tended to be a little lower than that of 2007/08 (other than the few temperatures recorded duiring the heatwave of late January and early February 2009). I suspect that most of the gradual change is due to the steadily increasing plant cover over the top; some ground-cover is also beginning to cover the exposed concrete walls. I have also added a little more soil on top of the roof.

About half of the mulch and loam to go on the roof was placed within the first three months; the other half went on gradually over the next couple of years. The fact that the increase in cover on top of the cellar seems to have made only slight differences to temperatures within the cellar suggests that most of the heat entering and exiting the cellar is via the door and exposed wall near the door (see Vaulted entrance).

I used a shade sale to keep some of the sunshine off the front of the cellar in the summers of 2006/07 to 09/10; in September 2010 this was replaced by a permanent corregated steel roof intended to keep both the summer sunshine and the winter rains off the wooden door and front wall.